At Grupo Treviño, we offer specialized solutions for various industrial sectors through advanced processes and value-added services. Our technological infrastructure and highly trained team enable us to develop functional, aesthetic, and high-precision components using both genuine leather and high-performance materials designed in our labs.

At Trevino Group, we use laser and CNC (Computer Numerical Control) cutting technology, which allows us to work with maximum precision on various types of materials. This process is ideal for producing complex parts, as it guarantees accuracy in every cut, uniformity between batches, and a reduction in waste.

The speed and efficiency of automated cutting optimize manufacturing times and ensure proper preparation for subsequent processes, maintaining consistent quality in every project.

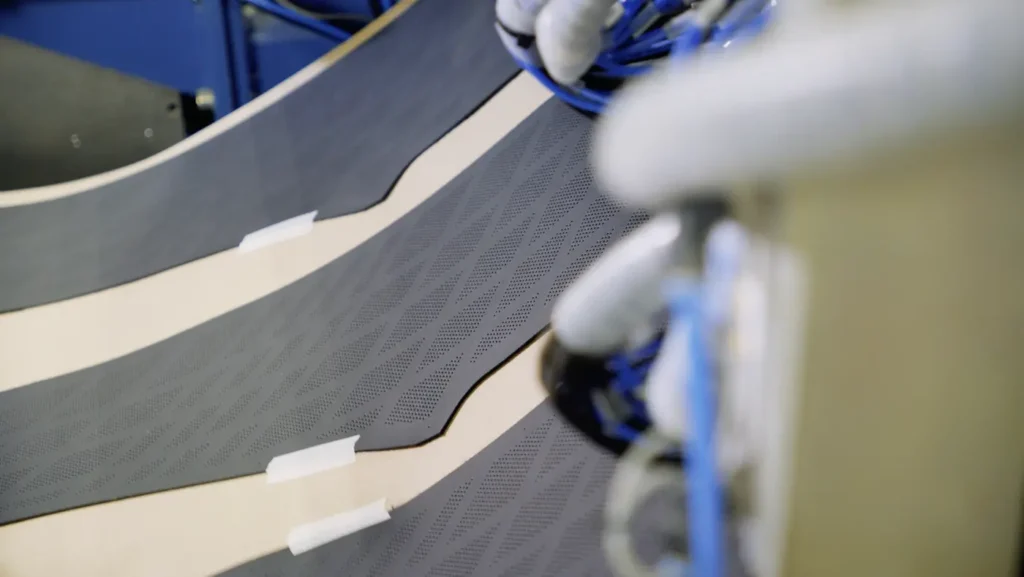

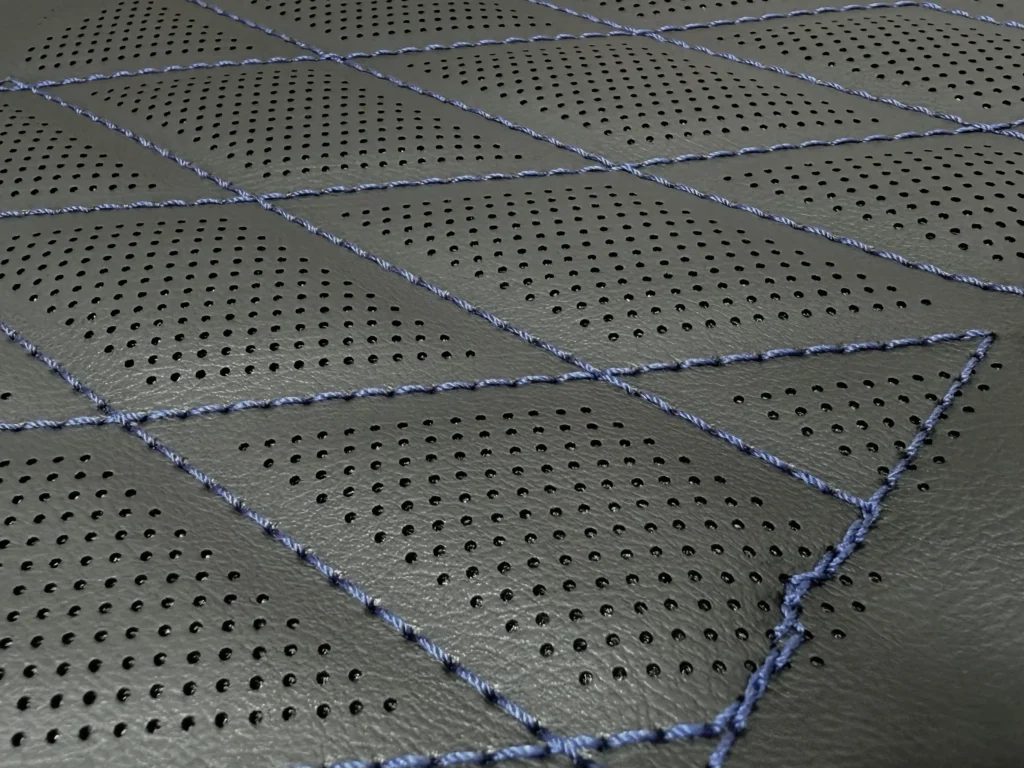

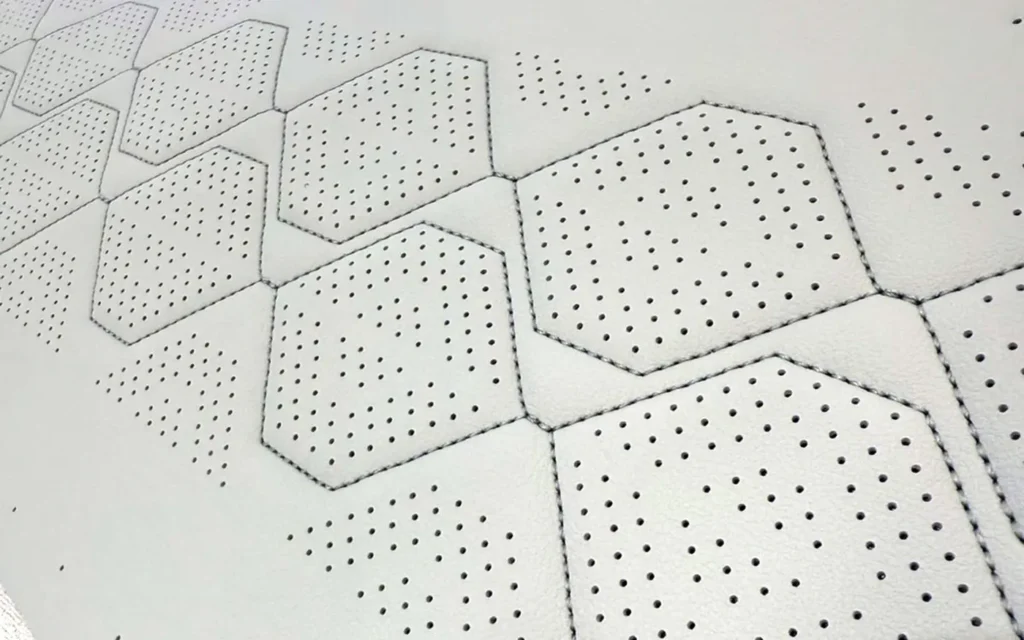

We offer a technical perforation service with automated machinery, designed to meet specific functional or aesthetic needs. The patterns can be customized according to the final design and application, with perforations that are precisely and homogeneously distributed.

This process is widely used to improve material breathability, apply visual details, or comply with regulatory requirements in sectors like automotive, furniture, or leather goods.

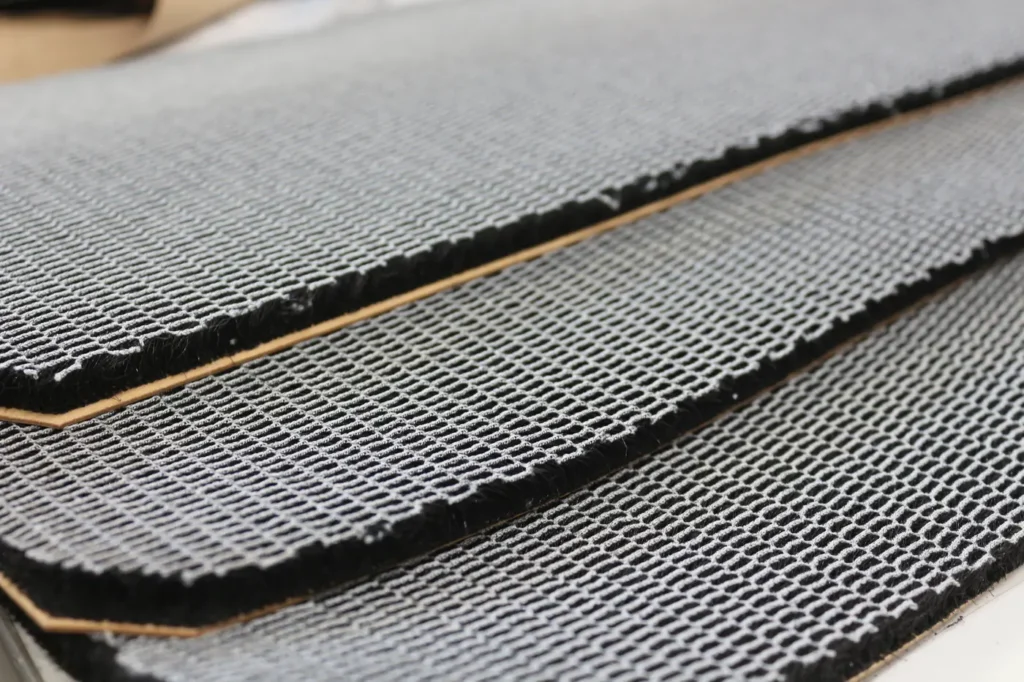

is a process in which two or more materials are fused to form a single composite structure. At Grupo Treviño, we use controlled temperature and pressure techniques to ensure a uniform and strong bond.

This service is essential for manufacturing products that require structural reinforcement, greater durability, or special finishes. It is applied to high-performance or natural materials according to client specifications.

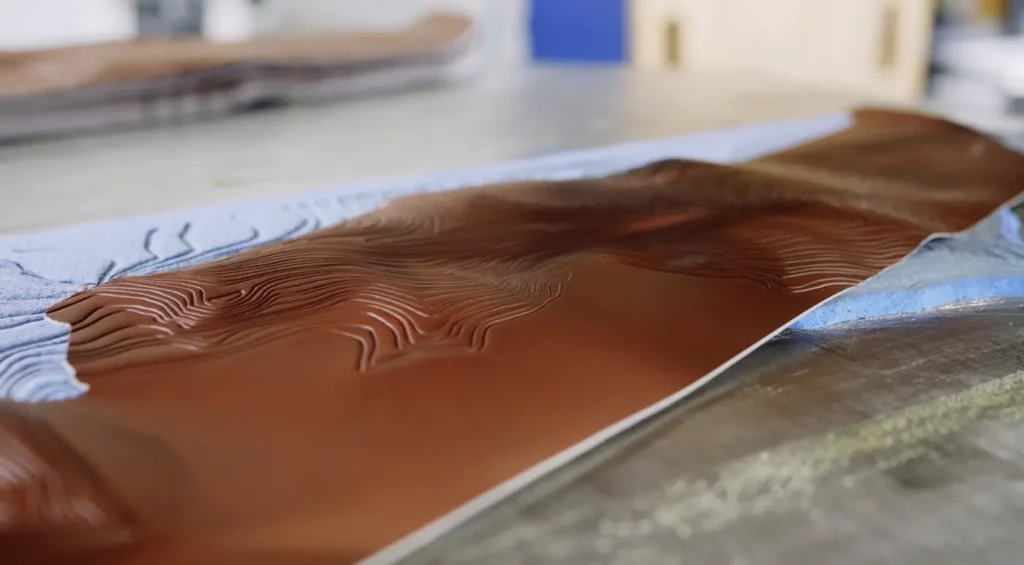

Through our automated embossing and engraving process, we offer the ability to integrate visual information directly onto leather or high- performance materials. This service allows us to apply logos, identification codes, serial numbers, or decorative designs with high definition and permanence.

It’s an ideal solution for those looking to improve product traceability or reinforce brand identity with professional finishes without altering the material’s integrity.

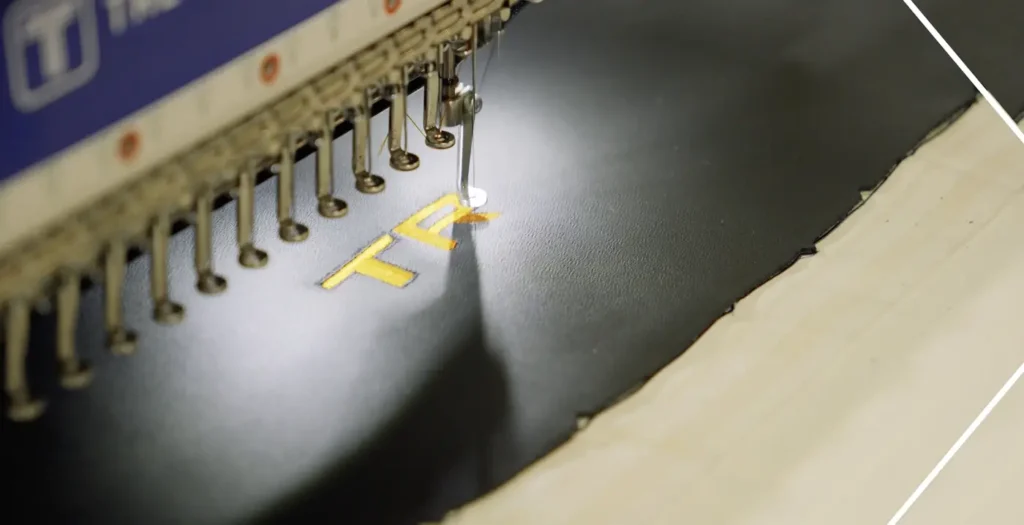

Industrial embroidery allows us to add graphic elements and visual details directly onto textiles or leather using high-precision digital machinery. It’s an ideal technique for products that require visual differentiation, brand identity, or aesthetic value.

This service is widely used in various sectors for decorative and branded accessories.

We have industrial sewing machines designed to work with materials of different thicknesses, offering strong and well-aligned seams. Additionally, we have expert artisans who perform custom finishes for every need. This service is essential for joining pieces with precision, whether in high-volume products or custom series.

The stitching is adjusted to defined technical patterns, meeting criteria for functionality, design, and durability for sectors such as automotive, furniture, fashion, and footwear.

Is a process that adds structure, volume, and resistance to materials, in addition to serving a decorative function. We use automated machinery that ensures uniform patterns, whether they are linear, geometric, or custom designs.

This service is frequently used on backrests, seats, panels, and items with comfort or insulation requirements, guaranteeing aesthetics, structure, and durability.

We perform component wrapping using specialized techniques for fitting, stretching, and fastening materials, ensuring precise and uniform finishes.

This process is key for applications where visual presentation, comfort, and feel are essential. It is ideal for automotive interiors, furniture, and accessories, adapting to different levels of complexity depending on the product.

Assembly involves integrating various elements or pieces into a single, functional component, using mechanical or adhesive fastening techniques. This allows us to deliver finished or semi-finished products that are ready to be incorporated into production lines or for direct sale.

This service reduces operational time for the client and ensures that each component meets exact technical specifications.

These capabilities not only allow us to create high-quality products but also position us as a strategic ally, capable of offering integral solutions that perfectly adapt to the specific needs of the clients. With Trevino Group, you can be sure that each product will be designed and manufactured with the utmost precision and care, providing you with incomparable value and exceptional performance.